Respirator Fit Testing: When It Matters and When It Doesn’t

CRYSTAL POLSON, RN, MSN, RESP-FIT accredited fit tester – Fit Test Victoria Pty Ltd

I know for many of you, fit testing probably feels like yet another box to tick along with all the health and safety measures that need to be in place – and enforced – at your workplace. And I’m here to tell you, you’re right. It can be a complete waste of time.

In this article, (presented at the Worksafely workshop, see page 22) I’ll break down the who, what, when and how of respirator fit testing. And I’ll tell you why, in some cases, you shouldn’t even bother with it. Let’s dive right in.

What is a Fit Test?

A respirator fit test – sometimes called a face fit test – is used to ensure that a specific respirator fits the user’s face properly and forms an adequate seal. This is critical because even the smallest gap between the respirator’s facepiece and your skin can let in harmful particles, gases, vapours or fumes.

There are two primary methods of fit testing – qualitative and quantitative.

Qualitative Fit Test Method

A qualitative fit test is a pass/fail method used to determine whether a respirator fits the user properly by relying on their sensory response to challenge agents. During the test, the user wears the respirator while being exposed to a harmless, aerosolised substance such as Bitrix (very bitter) or saccharin (very sweet).

The test checks if the user can taste or detect the agent. If the user senses the substance, this usually means that the respirator is a poor fit. If the user can’t sense the substance, then this indicates that the facepiece is creating an adequate seal.

Qualitative fit tests can be used for half-face and disposable respirators but not full face respirators. Because qualitative fit testing is subjective, it is less precise than the quantitative method.

Quantitative Fit Test Method

Quantitative fit testing is a method used to determine whether a respirator fits an individual properly by measuring the amount leakage around the facepiece seal. Unlike qualitative fit testing, which relies on the user’s sensory responses, quantitative fit testing uses specialised equipment to provide an objective measurement of fit.

There are two types of quantitative methods: Condensation Nuclei Counting (CNC) and Controlled Negative Pressure (CNP). The most common method you’ll see in Australia is the CNC method using either an AccuFit or PortaCount machine.

During the CNC test, the respirator is connected to the fit test machine via a tube. The machine analyses the air inside and outside the respirator to calculate a fit factor—a numerical value that indicates how well the respirator is sealing against the user’s face.

Quantitative fit testing is suitable for all types of tight-fitting respirators, including full-face, half-face and disposable masks.

Why is Fit Testing Important?

Without fit testing, there is no guarantee that a respirator provides its intended level of protection. A proper fit ensures that harmful contaminants, such as crystalline silica, are reduced.

Fit testing is a requirement under AS/NZS 1715:2009 standards and is now reinforced by new WHS amendments for tasks involving crystalline silica exposure. Ensuring compliance protects workers from health risks and employers from legal liabilities.

Does a Tiny Leak Really Matter?

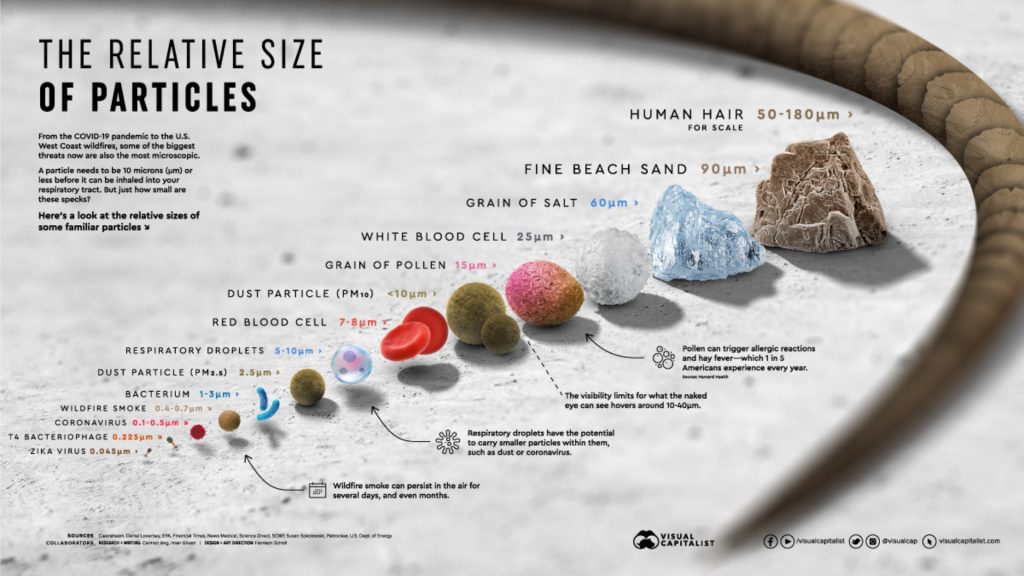

Even a small leak can undermine a respirator’s effectiveness. Very small particles – the ones that you can’t see – can be the most dangerous.

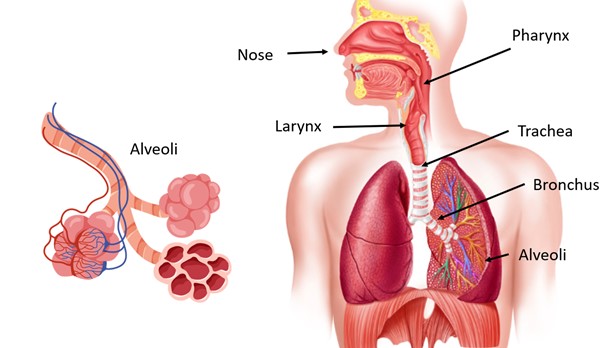

For example, respirable crystalline silica (RCS) can be a fraction of a micron (a micron is 1/1000 of a millimeter). Particles this small are called “respirable” and they’re invisible. These microscopic menaces bypass our upper respiratory tract and go straight to the alveoli (air sacs) in our lungs.

These tiny particles can stay airborne for days at a time depending on their size.

Particles larger than 10 microns typically get coughed or sneezed out. They don’t make it all the way down to our lungs.

Respirable airborne contaminants often penetrate deep in the lungs and cross over into our bloodstream, potentially harming

multiple organs and systems, including our immune and endocrine systems.

This is why silica can cause not only silicosis but also autoimmune diseases and kidney failure.

A proper fitting mask can reduce (reduce, not eliminate) your risk of breathing in harmful substances like silica.

Who Needs Fit Testing?

Fit testing is required for anyone using a tight-fitting respirator, regardless of job type, task, or duration of the work.

I’ve heard folks saying they don’t need to get fit tested because they aren’t working with silica. Or they don’t need to be fit tested because they only wear their masks for a couple of hours a day. Or they’re using disposable P2s that don’t need to be tested because they aren’t real respirators.

This bears repeating. Anyone required to wear tight-fitting respirators must be fit tested.

Fit tests should be done:

• When respirators are first issued.

• If the brand, model, or size changes (you must wear the exact respirator you pass a fit test in).

• If the wearer has significant weight changes, facial trauma, or dental surgery.

• Annually

Preparing for Fit Testing

To ensure accurate results, individuals getting fit tested must:

• Be clean-shaven. Facial hair – even stubble – compromises the seal.

• Avoid smoking or vaping 30 minutes prior to the test.

• Use a clean respirator.

For those unable or unwilling to shave, alternative solutions like loose fitting powered air-purifying respirators (PAPRs) are available.

When Fit Testing is a Complete Waste of Time

Now that we know what fit testing is, let me tell you when it can be a complete waste of time.

Not too long ago, I was at a worksite where the workers were exposed to lead and mercury when performing their job.

The Health and Safety Manager arranged for them all to get fit tested. As the workers lined up to get their test, I noticed that none of them had the right filters for the hazard. No particulate filter for the lead and no mercury filter for the mercury. A couple of the workers told me they had high blood lead levels. I bet they did!

It doesn’t matter if your mask fits like Cinderella’s glass slipper. If you’re wearing the wrong equipment for the hazard you might as well be wearing nothing at all.

And don’t bother with fit testing either if your workers don’t know how to use their RPE safely and appropriately. For example, if fuzzy faced fellas are shaving for the fit test and then growing their beards back, then the fit test was useless.

In these cases, fit testing becomes a mere formality – a tick box – rather than a meaningful safety practice.

Wrapping Up

Fit testing is a vital safeguard in respiratory protection, ensuring that equipment performs as intended and keeps out those harmful, microscopic particles like silica dust. It’s also a requirement under the AS/NZS 1715:2009.

However, fit testing becomes futile if you aren’t using the right RPE for the hazard, don’t know how to use your RPE safely and appropriately, or fail to maintain and store it properly.

Regular training, education, and adherence to a comprehensive respiratory protection program are equally critical to ensure your RPE works effectively when you need it most.

How Fit Test Victoria Can Help

Fit Test Victoria a new CMPA Associate Member are committed to making your life easier – at least when it comes to fit testing and respiratory protection.

We provide comprehensive respirator fit testing services at your workplace or at our Melbourne offices in Coburg and Oakleigh.

We also offer:

• Respiratory Protective Equipment Courses (learn how to use RPE the right way!)

• Fit Test Courses (if you want to bring fit testing in-house)

• Respiratory Protection Program Planning (a requirement under the AS/NZS 1715)

• Product trials and sales (you can use our masks to fit test and then purchase the ones you pass a fit test in)

Call us: 0488 688 454

Email: [email protected]

Visit: www.fittestvic.au

You must be logged in to post a comment Login