Silica submission – Safe Work Australia

DR ELIZABETH GIBSON, General Manager CMPA provides an extract from the CMPA submission to Safe Work Australia on the Consultation Paper: Impact Analysis of the Proposed Workplace Exposure Limits for 9 Chemicals (Consultation Paper) which includes respirable crystalline silica (RCS).

The focus of CMPA’s submission is on Respirable Crystalline Silica (RCS) (mining industry) as differentiated in the Consultation Paper and with reference to the related but lower risk quarry sector.

Submission

• Construction and demolition (C&D) waste recycling should also be included due to processing construction materials using the similar processes as quarrying (and often located at quarry sites due to Government requirements for recycled content blended with raw products) thereby incurring similar costs (in part).

• That the frequency for medical assessments be conducted every two years at a minimum for the quarry and C&D waste recycling sector.

• Time Weighted Average (TWA) Workplace Exposure Standard (WES) of 0.05 mg/m3 be retained for RCS:

• • Safe Work Australia silicosis claims for the quarry industry have been trending downwards from the year 2000 when excluding claims from the manufactured stone industry.

• • Efforts by employers have reduced with time the level of RCS exposure in the quarry and C&D waste recycling sectors demonstrated by most RCS personal monitoring data supplied by CMPA Members being below the current workplace exposure standard (WES) of 0.05 mg/m3.

• • RCS employee personal monitoring data point to accelerated silicosis not occurring within the quarry and C&D waste recycling sectors.

• Given the uncertainties around measurement at levels lower than 0.05mg/m3, any exceedances to 0.05 mg/m3 should trigger investigation of the sources of exposure and implementation of suitable control strategies as well as health monitoring.

Conclusion

Option 1 supported by CMPA: to retain the current TWA WES of 0.05 mg/m3 for respirable crystalline silica for quarry and C&D waste recycling sectors.

Discussion

Silicosis Claims

The Safe Work Australia statistical data for claims for silicosis demonstrate that the accepted cases for silicosis for the extractive industry have generally been decreasing from 2000, nationally (excluding where bagging of milled sand is undertaken in an enclosed space) see Appendix B.

It is understood that union officials may have their own agenda that appears to be beyond what is practicable or necessary for protection of the health of employees in the quarry/C&D waste recycling industry. This proposed halving again of the WES/Workplace exposure limit (WEL) may well lead to the closure of the extractive industry and thereby the construction industry (240,000 employees just in Victoria).

Workplace Exposure Standard /Workplace Exposure Limit

The Australian Institute of Occupational Hygienists (AIOH) recommends limiting worker exposure to RCS to as low as reasonably practicable (ALARP) to always be below an 8-hour time weighted average (TWA) guidance exposure value of 0.05mg/m3. (AIOH RCS and Occupational Health Issues Position Paper 18 November 2024).

CMPA Members’ RCS personal monitoring data (2014-2023) from quarries and C&D waste recycling has undergone a preliminary review by Dr Amanda Sillcock, Occupational Physician and demonstrated that:

• the readings on most of the samples were below the current WES of 0.05 mg/m3

• those that were higher were mainly older samples from earlier years

• this would suggest that there have been successful efforts to reduce the level of RCS exposure

• much of the work in quarries is performed outdoors so the risk is lower than for workers employed in enclosed spaces or working with manufactured stone

There is clear evidence that cases of accelerated silicosis are not occurring in the quarry and C&D waste recycling sectors as has been happening with manufactured stone.

This is distinct from what has been occurring with the manufactured stone sector and potentially the tunnel boring sector of the construction industry. The current evidence is that most, if not, all the recent/current cases are due to working with manufactured stone material rather than in the open-air quarry and C&D waste recycling sectors.

Periodic medicals

It is proposed that periodic employee medicals be conducted at a minimum of every two years for the quarry and C&D waste recycling sectors due to a lack of cases of accelerated silicosis in these sectors.

Thank you to all CMPA Members who provided their RCS personal monitoring data. The complete submission (including appendixes) will be available on https://cmpa.com.au/.

CMPA RCS Management Tools

CMPA is very much aware (historically records reports silicosis in quarrying in ancient times) of respirable crystalline silica (RCS) and the potential adverse impact on employees’ health and has been instrumental in raising this issue and subsequently compliance among

Members through:

• CMPA pre-employment health assessment proforma;

• CMPA periodic health assessment proforma;

• CMPA silica specific periodic health monitoring

• CMPA exit employment health assessment proforma;

• CMPA instructions for medical practitioners;

• CMPA Respirable Crystalline Silica Dust Management Guideline Issue 2 2022;

• CMPA On-line silica awareness training module for employees;

• CMPA Respirable crystalline silica awareness information for job applicants;

• Work Safely training including RCS and mask fit testing throughout Victoria 2024

Uncertainties in Measurement of RCS

Given the uncertainties (Australian Institute of Occupational Hygienists, AIOH) around measurement at levels lower than 0.05mg/m3, setting a trigger level (normally half of the WES) is not supported by CMPA. Any exceedances to 0.05 mg/m3 should trigger investigation of the sources of exposure and implementation of suitable control strategies as well as

health monitoring.

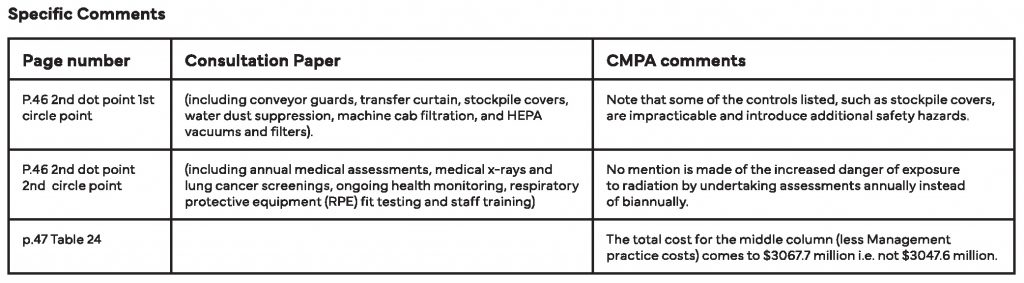

Costs

It is noted that in the Consultation Paper, RCS has been separated into two categories:

- RCS (excluding mining industry)

- RCS (mining industry)

This is due to the magnitude of incremental costs (WES 0.05mg/m3 being halved to WEL 0.025 mg/m3) being vastly greater for the mining industry. Additionally, the impact on the financial viability of the affected quarry/C&D waste recycling sectors would be far greater than the higher value export mining industry due to being a high-volume low-value local

consumption model.

The estimated total compliance costs due to the proposed WEL of $18.7 billion is ~700% greater than the total benefits of $2.5 billion. The percentage is expected to be underestimated due to low average business cost being given for small operations thereby detrimentally affecting their financial viability. Note small quarries are generally located in rural and

regional areas servicing local construction material needs by providing a competitive market of quality, rock/product type and price.

For RCS (excluding mining industry) the percentage is ~-80%.

Note the CMPA is actively seeking meetings with Safe Work Australia to detail CMPA’s progressive and proactive approach in this area (highlighted to the left).

From a practical point of view and due to the alarming, manufactured stone saga, public perception and overreaction may lead to unforeseen events such as a call for surfacing of all unsealed roads in Australia.

Dust minimisation, as low as reasonably practicable, at all sties is CMPA’s aim. Of significant importance is that many employees are family members which drives the owner in attaining WES.

You must be logged in to post a comment Login