Who is DK Sense?

Shaun Thirukonda on Who is DK Sense and how their automation systems are benefiting the Quarry Industry.

DK Sense: The Strategic Advantage for Smarter, Safer, and More Profitable Operations

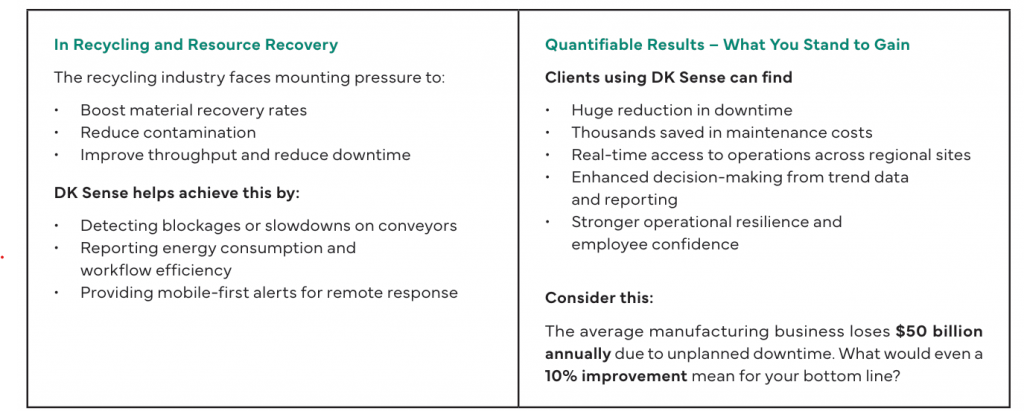

In the quarry, mining, and recycling industries, success today hinges not only on production output—but on operational resilience, intelligent decision-making, and the ability to pivot quickly. Yet many operations are still plagued by:

Unexpected equipment failures | Costly downtime |High maintenance overhead |Limited visibility across remote sites |Inefficiencies

in energy and resource utilisation

If your business faces these challenges, you’re not alone but we can tackle them with our system:

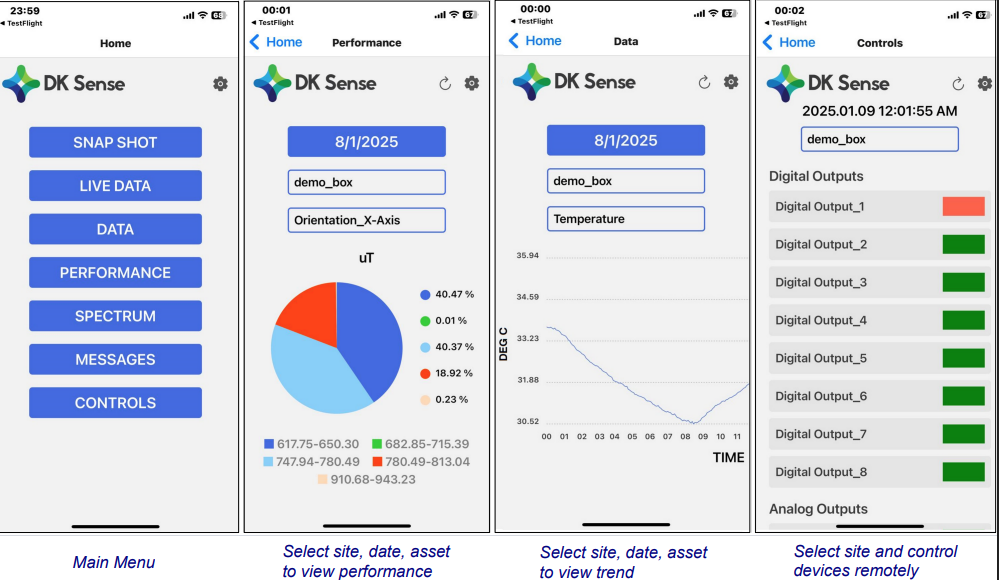

DK Sense—a purpose-built, intelligent industrial automation platform delivering real-time monitoring, predictive maintenance, and remote control across any industrial environment.

Why DK Sense?

DK Sense is more than an automation system—it’s an operational transformation tool. Built for harsh industrial conditions and designed for real-world challenges, DK Sense empowers leaders with:

Live operational visibility across assets and sites | Proactive fault detection and failure prevention | Centralised remote control and

automation |AI-assisted decision support and analytics | Real-time alerts and data on mobile and web platforms

Already deployed in quarry and recycling plants across Melbourne, DK Sense is enabling businesses to prevent breakdowns, enhance safety, reduce energy costs, and optimise output—all while protecting capital assets.

Who Benefits from DK Sense?

Designed for boardrooms as much as control rooms, DK Sense supports strategic business goals by addressing core operational pain points. It’s ideal for:

- Quarry and mining operators

- Recycling facilities

- Multi-site industrial organisations

- Plant managers and maintenance leads

- Safety-conscious operations

- Forward-looking businesses

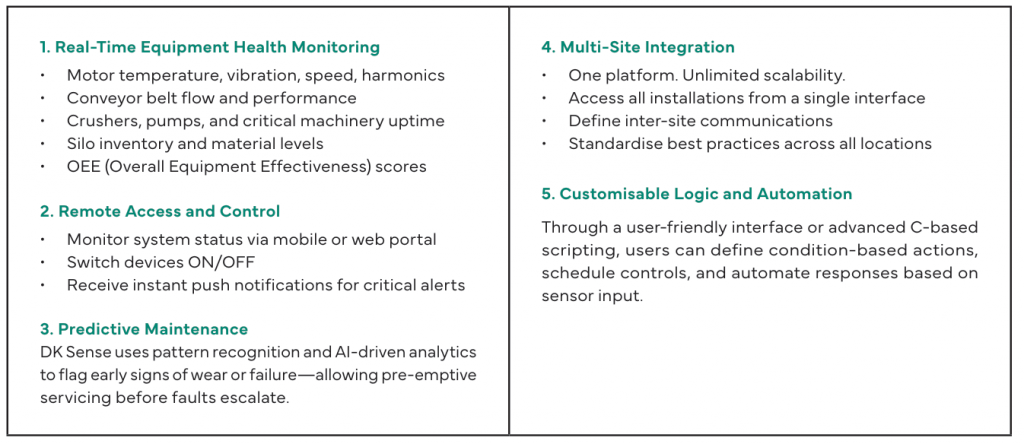

Core Capabilities – What DK Sense Delivers

Real-World Applications

DK Sense is currently used in the field for:

- Motor health analytics – auto-shutdown when limits are exceeded

- Conveyor performance tracking – including start/stop logs and idle intervals

- Silo level optimisation – prevent stockouts or overfills

- Greenhouse monitoring – ambient light, humidity, pH, and EC data logging

- System-wide environmental control – heating, cooling, ventilation

- Remote diagnostics – 24/7 data access and equipment logs

- Universal sensor integration – seamless retrofit with existing equipment

Enhancing Safety and Sustainability

Leadership today demands more than efficiency—it requires responsibility.

DK Sense supports both operational safety and environmental accountability by:

- Reducing the need for manual checks in hazardous zones

- Minimising energy usage through intelligent control

- Enabling condition-based alerts that reduce emergency interventions

- Improving overall site awareness for managers and stakeholders

Ready to see DK Sense in action?

- Support ESG and sustainability goals

- Future-proof your infrastructure

- Shows OEE in Real-Time

We invite you to book a free demonstration tailored to your industry and operational needs.

Call us on 03 9802 5516 Or reach out for a private consultation with our technical team.

Let’s explore how DK Sense can support your leadership vision, streamline your operations, and unlock new levels of efficiency and insight across your business.

DK Sense. Smarter Decisions. Safer Operations. Stronger Results.

DK Sense joined the CMPA in 2023 to support industry innovation with real-time monitoring, predictive maintenance, and AI-powered automation.

With extensive experience in quarrying and recycling industries, we aim to help members reduce downtime, improve efficiency and stay ahead of industry trends using our advanced sensor boards and cloud based industrial automation.

You must be logged in to post a comment Login