SILICA AND SILICOSIS

Recent plans by the National Occupational Health and Safety Commission (NOHSC) to reduce the National Exposure Standard for Crystalline Silica from 0.2mg/m3 to 0.13mg/m3 could have a massive financial impact on any quarry, concrete or recycling operation.

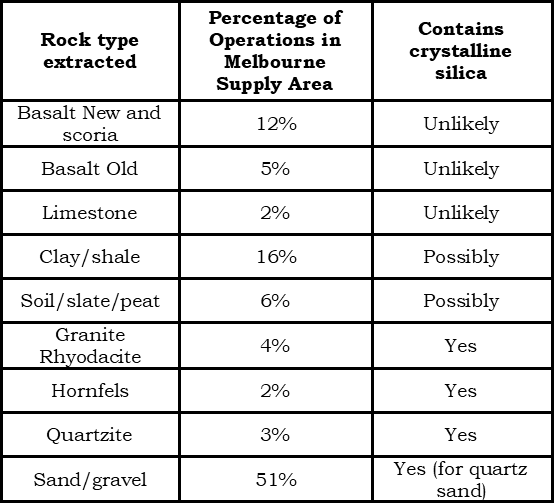

While the impacts will be restricted to operations involving the processing of materials containing crystalline silica, this still makes up a large portion of the industry. The table below is drawn from data obtained from the Extractive Industry Interest Area Review for the Melbourne Supply Area.

As can be seen from the table up to 81% of active extractive operations in the Melbourne Supply Area alone could be affected by the changes proposed by the NOHSC.

The CMPA’s submission has attempted to highlight the lack of evidence that the threat of silicosis is substantiated to justify a reduction in the exposure standard.

To combat the problem, the CMPA submission suggests the development of a monitoring program to collect information to form an accurate base for future reviews. In the meantime the opportunity should be taken to increase awareness of the potential hazards involved with working in the quarrying environment.

What is it?

Crystalline silica is 100% silicon dioxide (SiO2), but it is not its chemical composition that causes the problem, but rather the physical or crystalline structure. Respirable crystalline silica (small enough to breathe into your lungs) has been identified as a form of silicon dioxide that can lead to the formation of silicosis. This is a scarring of the lung tissue due to the inability of the body to breakdown, or dispose of the silica.

Testing for silica

If you plan to get your resource tested, ensure that you request a breakdown of the mineralogical components. In particular the percentage by weight of quartz/crystalline silica.

It is possible to have a high silicon dioxide content and a much lower quartz content. A sample of granite for example may have 78% silicon dioxide but only 36% quartz content. The remainder of the silicon dioxide is attributed to other less dangerous minerals from the sample.

Once you have had a mineralogical test completed on your sample, you may be able to make a preliminary determination relating to the risk of silicosis on your site.

A high percentage of silica does not automatically mean that there is a high exposure risk. For example, although most sand producers will have a resource with a crystalline silica content close to 100%, this does not automatically mean that their employees are going to contract silicosis. If the sand is extracted via an entirely wet process it would be difficult to breathe it into your lungs!

Other Monitoring

The tests used to determine the percentage silica content of a sample of rock can be utilised in the development of Material Safety Data Sheets. Accurate measurement however of the amount of silica dust that an employee is exposed to, can only be determined through ‘personal respirable crystalline silica monitoring’. This involves the employee attaching a device to themselves which takes in air and collects dust on a filter. The device is fitted so that it reflects the breathing conditions of the person. The filter from the device is then removed and analysed to determine the concentration of silica breathed in by the individual for that day. Under the current standard, the results from this test must yield a result less than 0.2mg/m3.

The CMPA has associate members who can provide these testing services. For more information contact the CMPA.

You must be logged in to post a comment Login