Screening Media Selection

The type of screening and size of the material will have a large bearing on the type of screening media that would be most efficient for the operation. We look at some of these factors. Th is is an extract from the CMPA’s Conduct Screening Operations Reference Manual.

SCREENING media contains apertures for the passage of undersize material. The most common types of screening media are:

- Grizzly Bars

- Perforated Plate

- Rubber (steel backed rubber)

- Rubber (standard rubber)

- Woven Wire

- Polyurethane

- Piano Wire

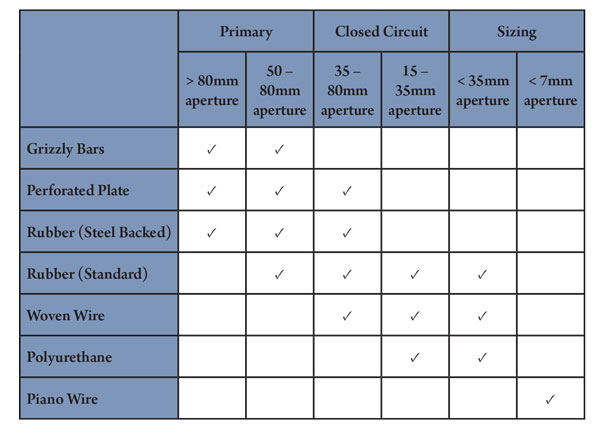

The following table may be used as a general guide for screening media selection in the construction materials industry.

GRIZZLY BARS

Grizzly bars are a heavy-duty screening element consisting of spaced parallel bars running in the direction of the material flow. The bars are usually tapered towards the discharge end to prevent pegging. Grizzlies are intended for coarse scalping and can be fixed, moving or vibrating.

PERFORATED PLATE

Perforated plate is usually manufactured from punched or burnt steel plate. It is used in many applications, but is primarily chosen when the material being screened is in large lumps, loads are heavy, material is highly abrasive or a long service life is required.

RUBBER

Rubber media is manufactured from two layers of wear resistant rubber with a tyre cord reinforcement between the layers to assist in cross-tensioning. It is most applicable to high frequency screens where pegging and blinding are occurring. They are less suited to highly abrasive materials.

WOVEN WIRE

Woven wire is the most commonly used and widely accepted screening surface. The wire is woven into a square or rectangular pattern. Wire medias are well suited to highly abrasive materials and high impact situations.

POLYURETHANE

Polyurethane screens, especially those manufactured by the injection-moulded process, can be produced with extremely accurate apertures as small as 100 micron. This type of precision is not available with rubber and consequently polyurethane is normally recommended for fine screening applications, such as heavy mineral recovery, washing and de-watering, etc. where the aperture is less than 5mm.

PIANO WIRE

Piano wire is a type of screening media made up of a number of single strands of straight highly tensioned wire spaced at the desired aperture. The wires are connected at either end by hooked edges providing a screen mat without cross wires. Piano wire is commonly used for sand screening, removal of dust or fines, or for sticky or hard to screen materials where square mesh would have difficulty in screening or handling the capacity.

You must be logged in to post a comment Login