Contain Your Dust – It’s a Must

TRACEY WALL, Communications Support Officer for Kinder Australia.

Conveyor belts are used to convey a variety of bulk materials and are exposed to constant and unrelentless environmental conditions, extreme wind, precipitation, heat and humidity. There is the real and visible damage that the elements have on the conveyor belt and it’s conveyed materials.

The harsh conditions conveyor belts are exposed to can lead to the issues of material run back and damaging material spillage, having negative impacts to productivity targets and operational bottom lines.

Selecting and installing the correct conveyor belt cover for specific applications and environmental exposure is critical. For applications where a consistent and high-quality finished product is imperative, conveyor belt covers act as highly protective barriers.

Keeping conveyor belts completely covered with the use of conveyor covers also result in less wear on critical high-performance conveyor components and the conveyor belt itself. Due to the overall reduced weight of installed conveyor components, protection provided from the conveyor belt covers can yield longer service life for conveyor hardware and the conveyor belt.

Dust becomes a concern when it becomes fugitive and airborne. It causes havoc and cost blow outs within every step in the production process.

There is also the ongoing costs and additional maintenance resources allocated to cleaning up dust and personal protective equipment required by workers when dust is not contained effectively.

Many operators have turned to conveyor belt covers as an economical, effective and safe solution for dust containment and airborne dust reduction. By covering up conveyor belts, the chance of dust emissions going outside the boundaries and negatively impacting nearby residents, communities and ecosystems is greatly minimised and the health and longevity of these communities remain intact.

The ability to supress dust emissions makes conveyor belt covers an asset to the conveyor, and a vital OHS implement. Uncontained, excessive dust in the air leaves operators exposed to potential health hazards. Long term inhalation of dust can lead to potentially irreversible lung damage and diseases such as silicosis.

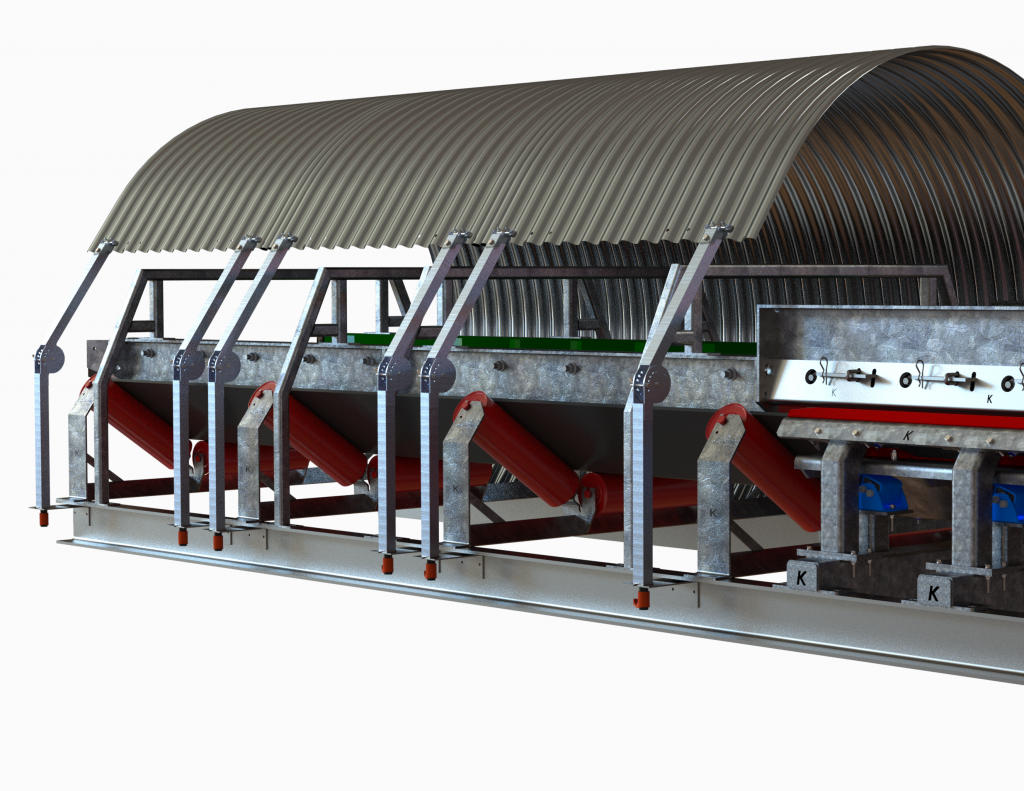

Durability, lightweight, aero-dynamic materials and ease of maintenance access are important aspects to look for when considering which conveyor belt cover is the best to select and install. With the evolution of engineering designs and high-quality materials currently available, conveyor belt covers can be designed and manufactured using a wide range of high-performance materials including galvanised steel, pre-lacquered steel, stainless steel and aluminium and fibre reinforced polyester.

From these engineered materials, conveyor belt covers can be designed for any size, shape, and application, as well as to suit the varying extremes of weather the conveyor belt is exposed to, and the level of protection required.

Traditional conveyor belt covers are high strength and versatile, shielding the entire conveyor belt from all weather conditions and suppressing dust emissions. Some also feature a patented lock/ hinge system, which can effectively withstand the extremities of heat, wind, humidity and precipitation over long periods. Conveyor covers that are hinged on both sides ensures ongoing access and simple maintenance from both sides of the conveyor.

Like conveyor covers, service props and struts also come in varying designs, shapes and sizes. These handy tools allow operators to gain access inside the cover to conduct routine maintenance. Service props are fully adjustable systems that hold up the conveyor belt cover safely and securely so that any maintenance inside the covers can be easily performed.

Containing dust is not an option, it is a must. For the environment, for your operators and for your productivity. Conveyor covers provide the best protection from nature’s harsh elements, whilst also keeping materials contained within.

For further information contact:

Kinder Australia 03 8587 9111 or

[email protected]

You must be logged in to post a comment Login