Delivering A Quality Road Product

CMPA Presentation at CCF Conference

IS it about who is responsible or is it about how we can ensure our community is gaining good public assets?

As a quarry owner, and a representative of quarry owners within the CMPA, I am very aware of the testing obligations with which we must comply with to meet the specifications as set in the market.

I am also aware that our sites are audited by GeoPave representatives, that our NATA registered laboratories are audited by accredited parties, our Work Authorities’ work plans and rehabilitation plans are audited by its regulators, our source’s rock quality are identified by GeoPave, and the list goes on. All I hear is ‘It is the quarry’s fault’, or ‘The product is out of grading by 1% on a post compaction testing result or a lot test’.

It may be that this is a fact, but I firmly believe it is not the reason why the principal’s expectations are not being met (in other words pavement failures are happening). I feel the variables are more heavily weighted in the area of the construction process on an outcome basis which can stretch over many days, even months.

I am also aware that we as quarry owners do not demand evidence of contractor’s compaction routine protocol with auditing and management evidence and ownership. We do not know if there is a protocol for identifying, tracking and proving the controls for addressing the many variables with respect to placement.

To us, it often seems one sided. We are a fixed target; we are a willing participant for accepting responsibilities as non-acceptance is near on impossible to agree to due to the financial implications.

Maybe in the aims of trying to resolve quality, tracking of product from the source, ensuring the correct volumes are used as per the specification, ensuring that there is evidence of skill and proof with respect to preparation of a stable platform on which to place our crushed rocks on, and then further evidence and proof with respect to placing and compacting our product is appropriate to consider.

In the past we continually applied the pressure onto the quarry whenever there was a failure.

Whenever issues arise, completion days are not met and compaction results fail – the quarry is not present when the contractor is negotiating with the principals on a settlement.

As they are not present, human nature takes over and blame is shifted. This is at the earliest days of conflict – and I believe has a very large bearing upon the continual increases in complexity of testing our products.

We are at a point today where our state’s resources are depleting through the continual obsession of higher and higher specification. Our association has clear evidence from many of our members advising us that their resources are limited in their life, and to add to this, the cost of replenishing those resources is absolutely financially inhibitive.

Know your supplier, know your contractor

I have always wondered why the long term users of our products are amicable and respectful of our art of quarrying. I think that it’s because they understand the complexity of our business. Many of them have visited our sites, and even have an interest in the art of quarrying. A few have even moved to the darker side of taking ownership within our sector!

Our business is about relationships. We make products to specifications set by others, even though we are the manufacturer.

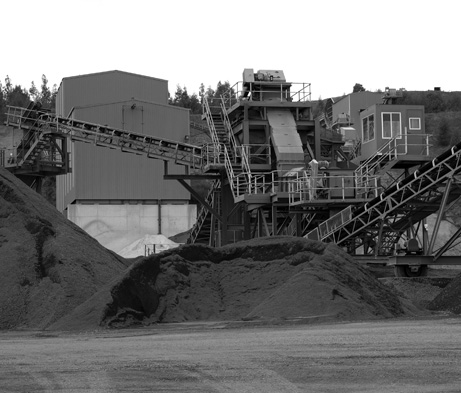

The art of quarrying is about processing. The processing activities in a quarry are broken up into four main designated work groups being extraction; processing; marketing, sales and dispatch; and administration and accounts.

We know those who we have a relationship with know the area where our quarry material is used and that they understand the use of our materials. Experience in this area has shown me a new source very quickly articulates these two very important pieces of the relationship.

Major complaints can be tracked back to a lack of understanding.

The customer who has established an “established compaction routine” appropriate for our material and each of their items of placement capital, and knows the area which they are working in, is without doubt going to have better outcomes and profit.

This compaction routine would cover issues such as:

- Source specific rolling routines

- Knowledge on moisture content for specific resource to achieve compaction

- The appropriate capital to carry out the task

- The appropriate training and auditing of these activities

Know your supplier, know the quarry

The quarry supplies a constant in that the crushed rock is within a range, a specification. The construction of a pavement on the other hand has unlimited variables all of which can contribute to pavement failure, such as:

- Moisture content of subgrade

- Stability of sub-grade

- Placement with or without traffic

- Winter / Summer

- Delivery rate to capital availability

This same customer knows whether his job has stability before placement of crushed rock commences; he knows whether he has appropriate drainage; he has proof and he has committed to this outcome. It’s a key hold point.

What we know about these customers is that they have an affinity with our rock, they work with the quarry in advance and on a daily basis. They communicate any concerns often linked from engineer, site supervisor or grader driver to quarry manager, weighbridge operator or pug mill/crushing plant operator.

These customers accept operators from the crushing plants visiting their sites to better understand the impact of mixing, blending and moisture content.

Inversely the quarry accepts their engineers and other parties visiting their sites. This is what a true partnership should be about.

With this close arrangement, potential issues are averted before they ever have a financial impact upon either party. Both of these parties understand there is a need for a relationship if they wish to prosper.

How many in this room today can say they have a true partnership with the quarrying system they use?

As we move forward, and the past world of VicRoads glory and site testing inspectors (and their charges) vanishes into the horizon, we need to address our obligations within this relationship.

The contractor is often working for a principal that has a contract that has:

- Security of payment addressed

- Rise and fall addressed

- A conflict resolution process

- A plan

- A specification

On the other hand, what does the contractor have between himself and the quarry? In my experience, there is often either a verbal communication or a quote at best. For hundreds and thousands of dollars.

Is this acceptable? Is this an area where conflict can fester? We need to know what our terms and conditions are. You as contractors need to know what we cannot do and what we expect.

The CMPA has been concerned for some time at the lack of written contractual obligations between its members and contractors or principles to whom they sell material. This situation has led to expensive disputes and litigation which could have been avoided.

The CMPA has developed a contract template for use in major contracts and a contract for owner drivers that meshes in with the major contract. It is stressed that both are designed as templates which are to be tailored to the situation they seek to record.

The CMPA believes that clarifying the responsibilities and obligations of each party will lead to greater efficiency for the industry.

The CMPA believes that it is not only in the interests of their members to have certainty in the relationship between them and a contractor and a principal but also that it is equally important for the contractor and the principal.

The CMPA believes that once parties become used to its contract template, it will be easy to finalise it for any job.

To assist in the uptake of this contract or any substitute contract the CMPA would like to see local government authorities entering into contracts with suppliers when the authority is the principal and instating that contractors they use enter into contract with the suppliers.

The CMPA is willing to talk to authorities individually to provide more information on the contract and its use.

It is extremely obvious that we are terminally ill. In the early 90’s this total costing charge was about 47 cents per tonne.

What we need to realise is that if we only deliver 20,000 tonnes in a year, the cost does not stay at $1.30 per tonne.

Clearly I have already mentioned that our resources of high quality material are diminishing. We are at a point in time where we need to reassess the material being used and the quality to which material needs to aspire for the outcome being achieved.

The specifications within the VicRoads database at the optimum end are for major freeway construction. It is our experience as quarry owners that these specifications are put upon us at local subdivision works.

We also see multiple quotes being sought and that customers have varying volumes and material types for the same project. We are wondering whether this is being covered under a non-conforming tender or just a misunderstanding.

We see situations where people are placing half a metre of Class 1 crushed rock in sub-divisional areas. We really wonder if this is the best use of a limited resource.

Maybe we need to be forming relationships with particular quarries, working out what is an appropriate product specific to the task, the area and the rock type being used.

Guidance on this issue must come from those who in the long run end up having to look after our public assets as they have the most to lose.

Ron Kerr, Honorary CEO

You must be logged in to post a comment Login