DUST MANAGEMENT

Most employers and employees of construction material processing business are aware that dusts can be a serious health hazard. Below is an extract from the CMPA’s Work Safely Reference Manual outlining two potential Dust Hazards in your workplace.

DUST HAZARDS – INHALABLE DUST

Inhalable dust is made up of all dust sizes that can deposit throughout the respiratory tract. It can include larger particles that deposit in the upper airways (nose and throat), smaller particles that can penetrate the upper airways and deposit in the lungs (thoracic fraction) and finer particles that can penetrate the alveolar region or gas exchange region (respirable fraction).

Dust may cause irritation and inflammation of the eyes, and aggravate pre-existing conditions. Repeated heavy contact to the skin may cause drying of the skin and can result in dermatitis, typically to the hands.

Repeated exposure to the fine dust may result in increased nasal and respiratory secretions and coughing. Inflammation of the lining tissue of the respiratory system may follow repeated, high level exposures increasing the risk of bronchitis and pneumonia.

For all general dusts, the inhalable fraction has an exposure limit of 10mg/m3 on the condition it is both of inherently low toxicity and free from toxic impurities (e.g. no asbestos content and less than 1% silica).

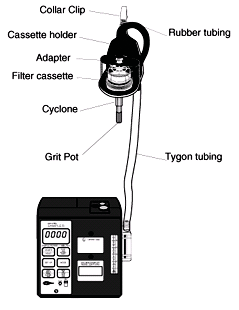

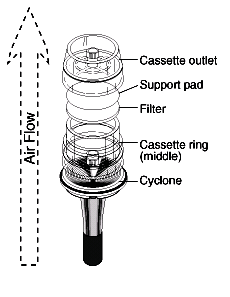

Sampling for inhalable dust is performed by an occupational hygienist according to AS 3640 – 2004, ‘Workplace Atmospheres – Method for Sampling and Gravimetric Determination of Inhalable Dust’.

Sampling devices used for inhalable dust are the UKA EA 7 hole sampler and the IOM dust sampler. These devices act as filter holders and are connected via tubing to the pump. Following sampling, gravimetric and/or chemical analysis of the filter can be performed on the filter sample.

DUST HAZARDS – CRYSTALLINE SILICA

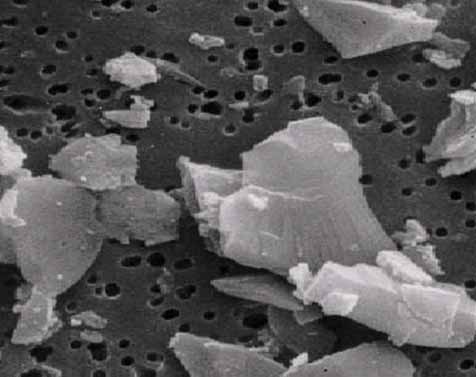

Crystalline silica (silicon dioxide or SiO2), also known as free silica, is a basic component of soil, sand, granite and many other minerals. Quartz is the most common form of crystalline silica. Cristobalite and tridymite are two other forms of crystalline silica. All three forms may become respirable size particles when workers chip, cut, drill or grind objects that contain crystalline silica. That is, the more recent the break, the higher the risk.

Analysis of various samples from CMPA sites throughout Victoria indicates the following approximate percentage of crystalline silica:

- Basalt < 1.0%

- Scoria 0.5 – 2.0%

- Clay 20 – 30%

- Granite 25 – 40%

- Hornfels 35 – 60%

- Siltstone 45%

- Sandstone >80%

- Sand > 90%

Variations from the above percentages will occur depending on the material source.

Respirable particles are the hazardous component. Respirable particles are very small and are able to get deep into the lungs. That is, the particles commonly have diameters of approximately 10 micrometres (1 micrometre is 1 millionth of a metre).

Prolonged exposure to respirable crystalline silica may, in some cases, cause silicosis in various forms:

- Chronic / classic silicosis: After 15 – 20 years moderate to low exposure

- Accelerated silicosis: After 5 – 10 years high exposure

- Acute silicosis:

- Between a few months – 2 years following extremely high concentrations

Crystalline silica has been classified by the International Agency for Research on Cancer as carcinogenic to humans, however the research on this is inconclusive and the ASCC has not classified it as a carcinogen. It has been shown in numerous studies that smoking will increase the risk to those exposed. Other health effects include increased risk of pulmonary tuberculosis and chronic obstructive respiratory disease.

In addition, consideration must be given to exposure levels for crystalline free silica to the general public. The EPA document ‘Protocol for Environmental Management – Mining & Extractive Industries’ sets a level of 3 micrograms per cubic metre measured as an annual average.

It is necessary to establish if there is quartz within the material being processed. A simple yes/no answer can usually be obtained from your geologist.

To establish the presence and percentage of crystalline silica, a sample would need to be tested using X-Ray Diffraction. This percentage however, will generally not have a clear relationship to the exposure to employees. It can however be used in the development of the MSDS and could be referred to when considering processing methods.

You must be logged in to post a comment Login