HISTORY OF EXPLOSIVES AND INITIATION DEVICES

REZA GHAEMI, Technical Service Engineer from Orica Mining Services reports on the history of explosives and initiation devices.

TODAY few people give much thought to the role that explosives play in their lives each day and how they are linked to our standard of living and our very way of life. Explosives provide the means to free up the vast resources of the earth for the advancement of civilization.

From crude beginnings over 1000 years ago the commercial explosives industry has gradually evolved through research and development into a Safe and Efficient provider of chemical energy to the Mining and Quarrying industries for the extraction of raw materials.

In Australia alone, blasting operations use more than 1 million tonnes of explosives and 12 million detonators per year. Sophisticated bulk and packaged emulsion explosives and electronic initiating systems have been perfected within the last 15 years which have led to dramatic improvements in the productivity of mines and quarries and ultimately improving the standard of living for all Australians.

The history of major developments in explosives and initiation devices is presented below in chronological order of discovery.

BLACK POWDER (9TH CENTURY)

Some records suggest that black powder, a mixture of saltpetre, sulphur and charcoal, originated in China in the 9th century, but that its use there was almost exclusively in fireworks and signals. A strong case can also be made that the father of black powder was the English medieval scholar Roger Bacon, who wrote explicit instructions for its preparation in 1242, in the strange form of a Latin anagram, difficult to decipher.

For the following 300 years, black powder was used solely as a rocket and gun propellant in Asia, Middle East and Europe. It was not until the 17th century that black powder was used for rock blasting. There is authentic evidence that it was employed in the Royal mines of Schemnitz, Hungary, in 1627.

The first application in civil engineering was in the Malpas Tunnel of the Canal du Midi in France in 1679. For various reasons, such as high cost, lack of efficient rock boring implements, and fear of roof collapse, the use of black powder in mining did not spread rapidly, though it was widely accepted by 1700 replacing the practice of fire setting as the principle method of loosening rock in the mining industry in Europe.

SAFETY FUSE (1831)

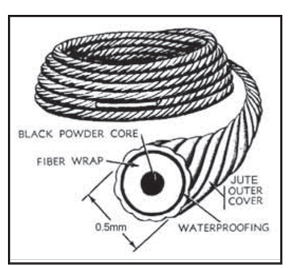

A major step forward in the safe ignition of black powder came with the invention of Safety Fuse by William Bickford, a leather merchant who lived in the tin-mining district of Cornwall, England was familiar with the frequency of accidents in the mines, and the fact that many of them were caused by deficiencies inherent in the quill fuse (goose quills were cut so that they could be inserted one into the other and then filled with powder). In 1831 he conceived the safety fuse, a core of black powder tightly wrapped in textiles, one of the most important of which was jute yarn. The safety fuse provided a dependable means for conveying flame to the charge. Its timing (the time required for a given length to burn) was amazingly accurate and consistent, compared to that of its predecessors, and it was much better from the standpoints of resistance to water and abuse. The present-day version of Safety Fuse is not very different from the original model. The core is coated with a waterproofing agent, such as asphalt, and is covered with either textile or plastic.

NITROGLYCERIN (1846)

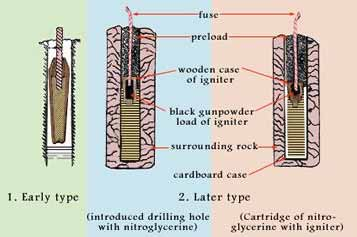

When Ascanio Sobrero discovered nitroglycerin in 1846, he found its properties so unpredictable and frightening that he warned against its use. Nitroglycerin was developed on a commercial scale by Immanuel Nobel and his son Alfred, marketed as “Nobel’s Blasting Oil”. In early applications, the liquid nitroglycerin was poured into the borehole and initiated by various types of black powder igniters.

Due to numerous explosion accidents in use and during transportation, use of nitroglycerin was banned in many countries in the mid 1800’s which led to the development of Dynamite by Alfred Nobel in 1866.

PLAIN DETONATOR (1864)

Swedish Inventor Alfred Nobel found that by enclosing a small charge of finely powdered black powder in a closed wooden capsule and leading the fuse through a tight fitting hole in the capsule plug he could reliably ignite nitroglycerin using shock rather than heat. Patents on this invention were applied for in 1864.

The Nobel patent detonator, the first detonating blasting cap (plain detonator), was born. Further developments, described in a later 1865 Nobel patent for the detonator made use of a small quantity of a primary explosive, mercury fulminate, pressed into a copper capsule which was crimped at one end of the black powder fuse.

Even today most experts regard Nobel’s invention of the blasting cap as the greatest advance in the science of explosives since the discovery of black powder as it showed the importance of initially detonating a high explosive with a shock wave-heat combination to achieve maximum energy, an important concept for the development of modern commercial explosives.

DYNAMITE (1866)

Swedish scientist Alfred Nobel invented dynamite, a high explosive consisting of sodium carbonate and three parts nitroglycerin to one part kieselguhr, a diatomaceous earth. In 1866 he obtained patents in England and in 1867 in Sweden, naming his new invention “Nobel’s Safety Powder”.

One advantage of dynamite over nitroglycerin was that it could be shaped into cylinders for easy insertion into boreholes. In 1875 Nobel discovered Blasting Gelatine by dissolving nitrocellulose in nitroglycerine and introduced Gelatine Dynamite a more efficient and powerful explosive. Nobel’s inventions of commercial blasting explosives were to dominate the field of blasting well into the 20th century and undoubtedly assisted the evolution of the Industrial Age.

ELECTRIC DETONATORS (1870S)

Electric ignition of gunpowder was first performed by Doctor Watson of England in 1745. This was achieved with an electric spark, which was unreliable since the powder was often scattered without igniting.

To overcome this problem Benjamin Franklin pressed the powder into a tin cartridge to achieve a faster and more reliable result (1750). Both Watson and Franklin used a Leyden jar, an early parallel-plate capacitor, as the source for the electrical spark.

Despite the uniqueness of this system, electric firing was not really introduced until the 1800’s. It was in the 1870s that the forerunner of the modern electric detonator was first assembled. In contrast to the spark-type ignitions previously used, it employed a fine, high-resistance wire soldered between two insulated leg wires and embedded in, or coated with, an ignition (flashing) mixture.

ELECTRIC BLASTING MACHINES/EXPLODERS (1878)

In 1871, Moses G. Farmer developed a hand-cranked dynamo especially designed to initiate electric detonators however, the first practical and widely used electrical blasting machine was invented by H. Julius Smith, an American, in 1878. It comprised a gear-type arrangement of rack bar and pinion that operated an armature to generate electricity. When the rack bar was pushed down rapidly it revolved the pinion and armature with sufficient speed to obtain the desired current. This current was released into the external, or cap, circuit when the rack bar struck a brass spring in the bottom of the machine. Smith’s blasting machine was improved and made in a range of capacities. These generator type machines are still in widespread use, although they have been replaced to a considerable extent by mains power firing and capacitor-discharge exploders.

The latter were first introduced in 1948 and rapidly found favour because of the high capacity for their weight and size. They have a battery power source for energising one or more capacitors and a safe, dependable means for discharging the stored energy.

DELAY ELECTRIC DETONATORS (1895)

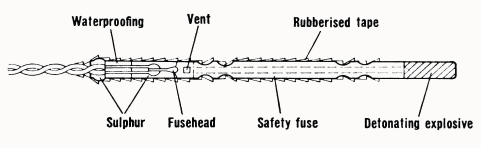

The early electric detonators were all of the instantaneous variety, but it was a logical step to attach a detonator to one end of a short piece of fuse and an electric igniter to the other end and in this way in 1895, H. Julius Smith introduced the delay electric blasting cap. This was the basis of modern delay electric detonators.

The next step that occurred in the late 1920’s was to make the fuse short (requiring a very slow burning composition) and incorporate it into a (vented) shell. This construction reduced the erratic burning rate of the fuse-type delay train and produced a more practical delay detonator.The delay powder train was improved further in the 1930’s by Eschbach, who introduced delay compositions that evolved so little gas that there was no longer a need to vent the detonator. This eliminated risk of pre-ignition of high explosive and also made it possible to provide fully waterproofed assemblies which gave delay times much more regular because of the removal of variable venting effects.

Short-interval delay detonators were introduced in 1946, having delay intervals in milliseconds rather than seconds.

DETONATING CORD (1902)

In nonelectric blasting the most significant development, following safety fuse, was detonating cord which resembles safety fuse but contains a core of high explosive instead of black powder. Although a variety was in military use in Europe in the 1870’s, it was not until 1902 that a form of detonating cord, a tin tube filled with picric acid, was first used in a mining application. Modern detonating cord consisting of PETN in a fabric braid was introduced in 1938.

ANFO (1950’S)

Ammonium Nitrate, a powerful oxidiser, has been considered as an inert substance, but it is well known after some famous disasters, that although its sensitivity is very low when the product is pure, its sensitivity increases greatly in the presence of combustible impurities, and can therefore be detonated with an appropriate booster or cartridge explosive.

The explosive properties of ammonium nitrate were first formally utilised in 1867 by replacing a portion of nitroglycerin as an ingredient in dynamite. The Ammonium Nitrate fuel oil, ANFO, which entered the market on a large scale around 1955, was the first commercial explosive to really capture an important part of the explosive market. During the 1960’s ANFO replaced dynamite in dry holes because of costs savings, safer handling characteristics and mechanical loading ability.

WATER GELS (1950’S)

In 1957 a professor at the University of Utah, Dr Melvin Cook began experimentation with a mixture of AN, water, guar gum (a gelling and cross linking agent), and aluminium. His resulting explosive material called “slurry” was water resistant and of high density and had a relatively high detonation velocity.

The new technology spread rapidly with explosives suppliers introducing similar products using TNT, smokeless powder and paint fine aluminium as sensitisers and energisers. These early water gels were only used in bulk applications until the development of chemical gassing in 1964 enabled slurries to enter into the small diameter market. Water Gels have been almost totally superseded by Emulsion explosives.

CAST BOOSTERS (1950’S)

Aft er World War II, during the 50’s and 60’s there was high availability of low cost military high explosives that had been released to the commercial market. The availability of these products together with the need for compact high detonation pressure boosters for the initiation of ANFO products and later, water gels, prompted the development of the cast booster.

Cast Boosters are cap-sensitive explosives that typically contain the high explosive trinitrotoluene (TNT) as the casting material. Different molecular explosives are mixed into the melted TNT and impart additional energy and/or sensitivity to the booster.

Where extra sensitivity is required for pick up from low strength detonating cords, different manufacturers have used various techniques to impart the desired sensitivity, including; high percentage of PETN in the primer, plasticised PETN tubes fitted over the pins before pouring, detonating cord wrapped around the pins, sealed plastic bottle of PETN in the centre of the booster).

EMULSION EXPLOSIVES (1961)

The history of emulsion explosives began in 1961 when Richard Egly and Albert Neckar of Commercial Solvents Corporation filed a patent application with the U.S. Patent Office for a blasting agent composed of a blend of a water-in-oil emulsion and a solid oxidizing agent such as ammonium nitrate. This was granted in

1964 as U.S. Patent 3,161,551. Rather than looking for a new type of explosive in the form of an emulsion, they were trying to make a waterproof ANFO. Subsequent developments in the 1960’s and early 1970’s resulted in emulsion explosives with explosive characteristics of minimum diameter and detonation rate comparable to the various grades of dynamite. In addition, emulsions were developed with characteristics which allowed their safe and efficient use in high-volume bulk loading systems.

NON-ELECTRIC DELAY DETONATORS (1967)

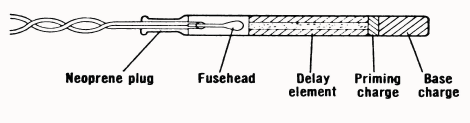

An initiation system comprised of low core load detonating cord att ached to a delay detonator was introduced in the U.S. in 1967, while almost simultaneously a system utilising a plastic tube with a very thin internal coating of aluminium and the high explosive HMX, attached to a delay detonator, was introduced in Sweden.

The inventor was Dr. Per Anders Persson. This “shock tube” based system carried the trademark name of “Nonel®”. The Low Energy Detonating Cord (LEDC) systems never rose to prominence and the one incorporating shock tube has become the dominant initiation system worldwide.

ELECTRONIC DETONATORS (1970’S)

Electronic delay detonators, or electronic blasting systems (EBS), have been under development since the 1970’s. The principle advantage of the electronic detonator is very precise timing. An integrated circuit chip and capacitor contained inside the detonator, controls the initiation time. To arm and fire the detonators, a specially coded firing signal is required which makes the system immune to extraneous electrical hazards.

The CMPA thanks both Frank Santoro and Reza Ghaemi from Orica Quarry Services for their production of this article.

References – ISEE Blasters handbook 18th edition; The World of Explosive (website); Wikipedia; High Explosives & Propellants, S Fordham.

You must be logged in to post a comment Login