Manage your Geotechnical Risk

We recently updated the CMPA ‘Working Safely with Geotechnical Risk in Quarries’ Guideline, with Issue 4 providing more detailed information for quarry managers, leading hands and operators in controlling geotechnical risk.

The following new sections have been added:

8.3 Unused or infrequently used roads and quarry benches

If roads and benches are out of use for extended periods, then access to the roads and benches should be physically blocked so they are not accessible. No Entry signposts should be installed and the Traffic Management Plan amended to suit.

Prior to re-opening a road or bench an inspection by quarry manager should be undertaken to ensure edge protection, drainage and line of sight is adequate, and to identify any ground movement, instability including rock fall and weathering.

There are generally two types of run off areas:

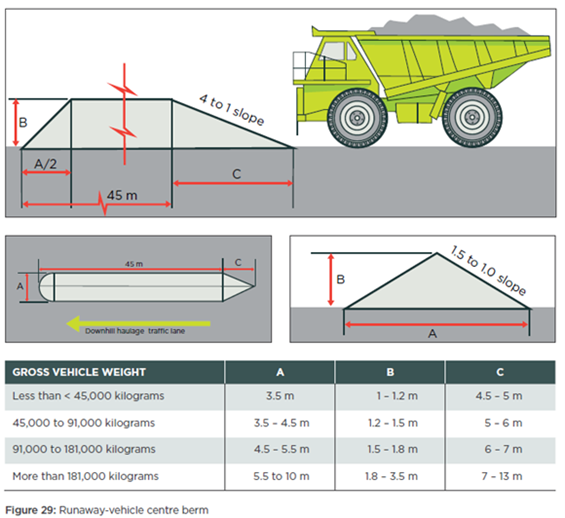

- Centre berms are piles of loose granular material placed strategically along the centreline of the road. In the case of brake or retarder failure, the driver manoeuvres the vehicle in line with the berm so the vehicle straddles the berm and is brought to a halt. Consider the following when installing centre berms:

- The nature and size of the equipment that might size of the equipment that might need to drive on to or straddle the centre bench.

- Using material to provide sufficient drag on the vehicle.

- Positioning of the centre berms so vehicles have limited time to pick up momentum.

- Adequate space between berms to allow the driver time to position the vehicle.

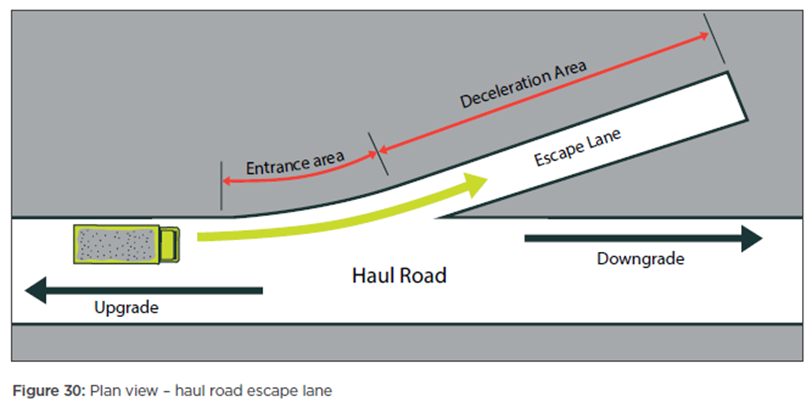

- Escape lanes can be used where space is available. Consider the following when installing escape lanes:

- Size and expected speed of a runaway vehicle that might be required to enter the lane.

- Alignment of the lane and the road.

- An operator of a runaway vehicle should be able to steer the runaway vehicle into the lane.

- Size and length of the lane. The lane needs to be wide enough and of sufficient length to allow vehicle access and time for it to slow and stop.

- Construction material for the lane should offer a high rolling resistance and not tend to compact.

8.4 Run-off areas

Run-off areas are a method of slowing trucks down, when they have had some sort of brake/mechanical failure.

Run-off areas should be clearly signposted in advance of and at the location, included on the Traffic Management Plan and communicated through inductions.

Situations where consideration should be given to run-off areas in a quarry include:

- Road grades at or near the maximum grades e.g. 1/10 over a long distance

- Steep grades combined with switchback corners

8.5 Other General Controls for Haul Roads

- If the design is for a major feeder road, the road width will need to be increased accordingly;

- Right of way should be established and signposted;

- Overtaking bays should be established and signposted;

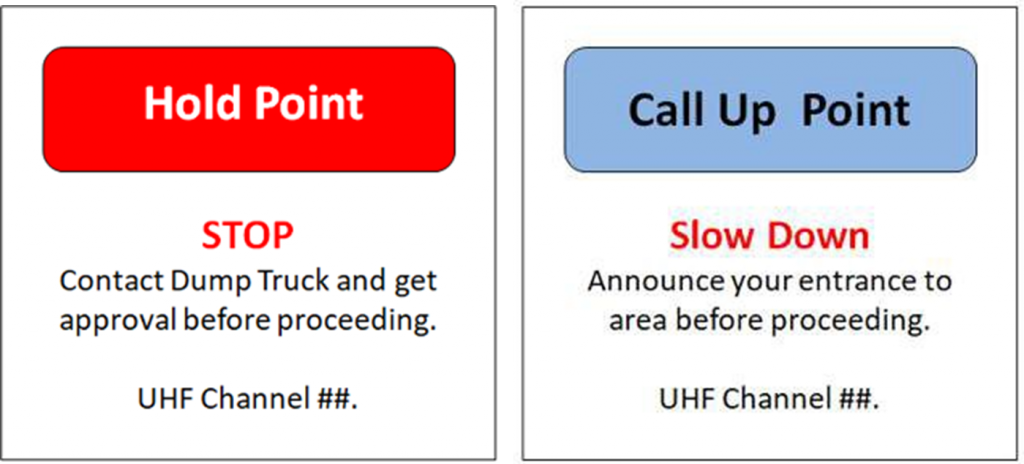

- Hold and call Up points should be established and signposted;

- Safe distance for vehicles passing should be established, documented and communicated;

- Blindside turns should be eliminated or limited as far as is practicable;

- Bends should be established and utilised to reduce speed;

- Driver’s line of sight needs to be taken into account on bends, corners, rises/crests and areas where sun glare, shadows, wind direction and associated dust movement may affect the line of sight;

- T- Intersections should be at 90 degrees to the through road;

- Where applicable provide delineation of roads using guideposts with reflective tape/markers;

- Utilise speed humps and or bends in roads to reduce speed in critical areas;

- Roads should be designed as free draining to minimise the pooling of water creating potholes;

- The selected road camber should not enhance the potential to slide in wet conditions;

- Drains, culverts and channels should be protected from traffic;

- A dust suppression program for haul roads should be established and implemented.

Note: New sections relating to ‘Edge Protection Berns’ have also been added; these sections will be featured in the next issue of Sand & Stone – Issue 144.

For copies of the updated Guideline, visit the CMPA website

You must be logged in to post a comment Login