Minimising Rehabilitation Bonds – Sand Quarries

Dr Elizabeth Gibson, General Manager CMPA provides some highlights from the Workshop.

A substantial day was held for CMPA Members and other interested industry contributors in Pakenham. The purpose of the workshop is to provide participants with appropriate best management practices required to minimise rehabilitation bonds and to develop a CMPA sand quarry progressive rehabilitation guideline table of contents. The Guideline when developed will also be a mechanism that may be used to keep rehabilitation bonds manageable, minimise liabilities and assist with ensuring legislative

responsibilities are met.

The one-day workshop was an interactive process which encouraged the active involvement of the participants rather than a lecture session. The Workshop was held on Thursday 20 June 2024 at the Cardinia Club Pakenham. Below is the agenda for the Workshop.

ERR expectations for rehabilitation

Rohan Bett gave a thorough detailed presentation on ERR’s expectations and answered questions from the audience throughout.

Ways to reduce your bond – recap

• Minimise the disturbed footprint

• Move materials once if possible (minimise stockpiling and reloading costs)

• Minimise the need for truck and shovel operations

• Place required materials within short dozing distances of their final location

• Understand the total costs of extracting and rehabilitating each area of the quarry and use this to inform operational decision making

• Maintain good housekeeping

• Remove derelict plant and equipment from site

• Contain spills, refuelling areas etc.

• Progressively rehabilitate to build confidence in your rehabilitation methods to establish safe, stable and sustainable landforms

• Match terminal and operational faces to approved rehabilitation profiles where possible

• Assess rehabilitation sequence to minimise rework

Transitional Measures Available (for reducing rehabilitation bonds)

Sand Rehabilitation bonds

Sand quarries may have high rehabilitation risks due to:

• Residual risk of slimes dams and ongoing monitoring and maintenance requirements

• The risk of erosion and sediment transfer within the rehabilitated batters

• Local instability impacting overall stability over time

• The nature of the material resulting in difficulty returning the land to a safe, stable and sustainable landform

• Rehabilitation requiring large earthmoving volumes

• Identified non-compliances, including over extraction resulting in insufficient material to complete rehabilitation

Minimising rehabilitation bonds in a sand quarry – Letter-based commitment

The rehabilitation liability to be created could be reduced in the work plan in several ways:

• Using smaller stages to reduce the disturbance at any one time.

• Committing to a smaller area of maximum disturbance.

• Extracting the terminal batters to match the grade of rehabilitation batters.

• Including a commitment to have only a certain number of batters requiring backfill at any one time.

• Following discussions with the authority holder it was determined that the full area of extraction would not be open for some time as the site was only just beginning development.

• Rather than updating the work plan a letter-based commitment was used to commit to defined stages upon which the bond can be based. This has now been revised following the first year of operation and a new stage defined.

• Outcome: reduced the liability, its impact on the environment, encourages progressive rehabilitation whilst also reducing the cost to the operators, particularly during site development.

If the rehabilitation contains closure criteria the rehabilitation would be assessed against them.

Return of Rehabilitation Bond

Closure criteria:

These are not the activities (e.g. shape and rip) but how ERR measure that the activities have been completed and successful.

• They should measure the success of activities in meeting the closure objectives.

• The criteria need to be realistic about what can be achieved.

• The criteria may require update over time as additional knowledge of the site is gained.

• There should be inputs from stakeholders into the criteria.

• Ensure they are SMART goals.

• Must be monitored over time and managed so that you can demonstrate success.

Surrender of a work authority does not necessarily mean that the rehabilitation bond would then be immediately returned. The bond will be returned once the rehabilitation has been completed in accordance with the rehabilitation plan and is assessed as being likely to be successful.

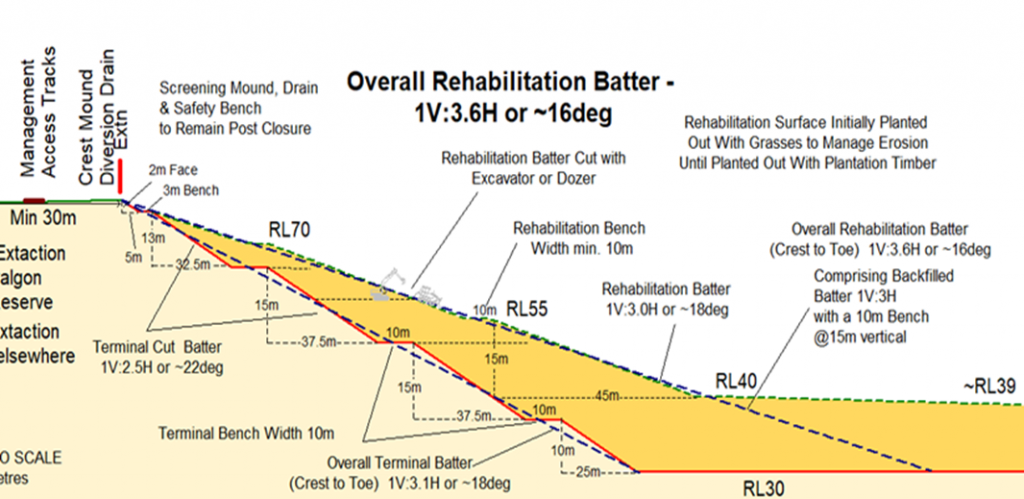

Operative/earthworks in sand quarries

Cameron Black gave an interesting presentation advising that the work plan and rehabilitation plan must be understood in order to minimise rehabilitation bonds.

• Be aware of any Work Plan requirements, ie bunds, screening, planting

• Understand your final landform and how you will achieve it

• Set short to medium term goals, i.e. overburden to move and by when

A presentation was also given by Robbie Viglietti (Sand Supplies) see front cover story of Sand & Stone.

The CMPA will now prepare a Minimising of Rehabilitation Bonds and Progressive Rehabilitation Guideline. If you are interested in participating in the working group please email elizabeth,[email protected]. Thank you again to all the presenters.

You must be logged in to post a comment Login