Quarry success DRIVEN by new technology

ANDREW ZUPO, Director of REAZ Australia Pty Ltd reports on the most significant technical advancement seen in drives in the last 30 years.

We all agree it is imperative to keep in touch and move with the latest developments in technology from around the world. Particularly one which is inherently an environmentally cleaner device than current technology utilises, whilst simultaneously achieving higher productivity efficiencies, and one I am proud to say proves Australian Engineers are leaders when it comes to embracing new, more efficient technologies.

Andrew Zupo, Director of REAZ Australia Pty Ltd and REAZ Senior Electrical Engineer David Fisher (B.E.Elec) each have over 25 years’ experience in the area of Variable Speed Drives including design, supply, install and commissioning of various brands. Together with REAZ National Sales Manager Neville Price, the trio have put their weight of experience behind the latest development in Variable Speed Drive technology in the format of the Yaskawa U1000 Matrix Variable Speed Drive.

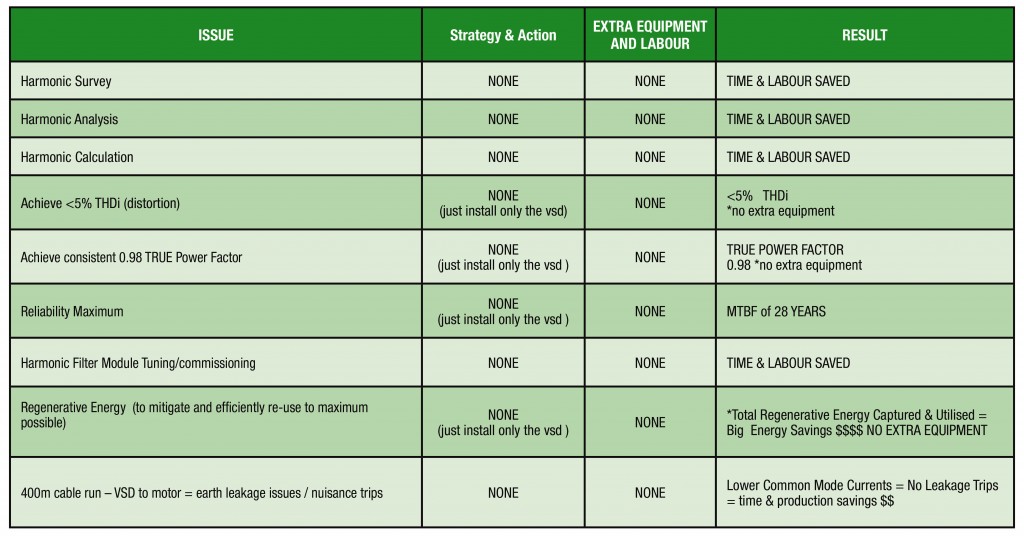

“There is no doubt that the Yaskawa U1000 Matrix VSD is the most significant technical advancement seen in drives in the last 30 years!” The proof of this can now be seen from the success of the recently completed Hanson Quarry Project in Hobart Tasmania where the Matrix VSD seamlessly solved some serious issues facing the project. As the site photo shows, the project involved 3 large Decline conveyors and as those in the industry know, this presents big challenges in the mitigation of several headaches including HARMONICS, POWER FACTOR and POWER REGENERATION along with several others, none the least of which was a 400 metre cable run from drive to motor!

SITE PHOTO: Hanson Hobart Quarry, x3 Large Rock conveyors, downhill, total conveyor system length approx. 800 metres with a decline of approx. 86 metres. Also x3 motor/gearbox’s and x3 variable frequency drives

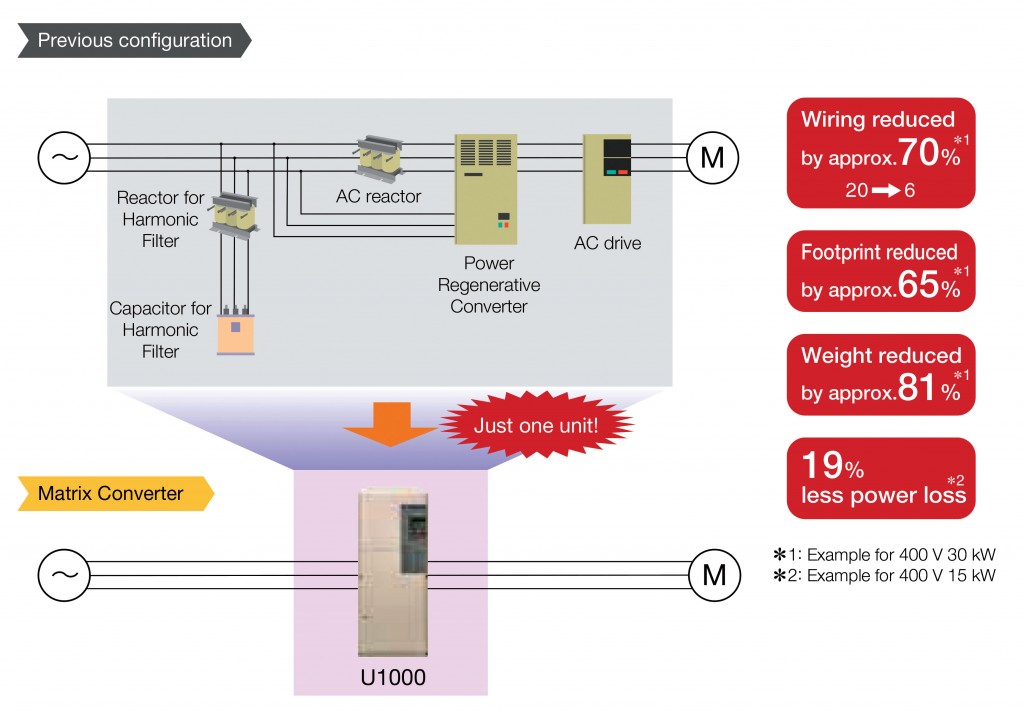

As industry knows these problems can be solved with existing technology but, it relies on expensive additional switch gear and equipment such as AC REACTORS / HARMONIC FILTERS / INDUCTORS / POWER FACTOR CORRECTION EQUIPMENT/ POWER REGENERATIVE CONVERTER along with extensive Engineering time and labour to tune and commission all this extra equipment. All this extra material is expensive, bulky and energy consuming. The Yaskawa U1000 Matrix VSD requires NONE of this extra equipment it is simply 3 wires in – 3 wires out, as the diagram – Compact Matrix drawing shows.

“When starting out on any “new technology” journey you need the help of good people and REAZ certainly found that in Craig Cahill and Terry Hickey of Gordyn & Palmer (CMPA Associate Member) who, upon presenting the Matrix to them immediately embraced the new technology and encouraged us to pursue potential applications for the device.”

Eventually REAZ approached the parties involved in the Hanson Quarry Project where they quickly realised this game changing technology was the answer for them.

Daniel Hall, Director of Hi Tech Electrical Queensland, the contractor for the Hanson Project, instantly realised the capabilities of the Matrix and had no hesitation recommending the Matrix to Hanson Project manager Bob Kammerman who also gave it his stamp of approval. Daniel and his expert team successfully completed the project with the Matrix VSD’s along with the assistance of David Fisher (B.E. Elec) Senior Electrical Engineer from REAZ who commissioned the drives.

“The beauty of the Matrix is in its simplicity – that is – its not so much what it has but what it does not have.”

As the table displays below, the Matrix achieves the stringent required results inherently so it is simply THREE WIRES IN – THREE WIRES OUT!

NOTE THE FOLLOWING for THE MATRIX –

- Has NO DC BUS

- NO POWER CAPACITORS

- THDi of <5%.inherently nothing extra needed!

- 0.998 POWER FACTOR inherently!

- TOTAL REGEN inherently! (=$$ energy savings) These facts and others is why the matrix comes with a stated *MTBF of 28 YEARS! * (Mean Time Between Failure)

**ALSO…The MATRIX comes complete with built in software to automatically record the amount of energy which has been Regenerated and utilised. A great asset when calculating / forecasting cost savings **

Yaskawa is the largest manufacturer of drives in the world! It turns over $4B a year in drives and employs 8,000 people globally. Yaskawa drives have an absurdly low failure rate.

In a short time REAZ has successful Matrix installs across several sectors of industry, they are a new Associate Member of the CMPA and are growing rapidly. We are proud to say this proves to us that Australian Engineers are industry leaders when it comes to embracing new, more efficient and environmentally friendly technologies.

Power authorities are now making it clear to industry that HARMONICS and POWER FACTOR issues MUST be mitigated and the Matrix lends itself perfectly to this.

REAZ is very excited at moving into the future and we are proud to put our name behind the Yaskawa U1000 Matrix Variable Speed Drive.

For further enquiries contact REAZ Australia Pty Ltd – Andrew Zupo, Director 0423 933 339 or Neville Price, National Sales Manager 0474 536 749.

You must be logged in to post a comment Login