Dealing with Asbestos

Recycling of construction and demolition materials is an important industry in Victoria. It is important to ensure that Members are meeting their obligations under the related asbestos legislation. Following is a summary of guidance material available from the WORKSAFE website.

AS a result of the OHS Consultancy sessions that have been occurring around Victoria, the CMPA has become aware that a number of Members are accepting inward materials. As such, now is an opportune time to refresh Members with information on complying with asbestos laws in relation to recycling construction and demolition material (C&D materials).

To determine whether the following guidance is applicable to the C&D material being recycled, ask:

- What is the source of the C&D material?

- What does the C&D material consist of?

- When was the building or structure built?

- Utilising the above information, is the C&D material for recycling likely to contain asbestos?

Yes: Process C&D material utilising the following guidance as a reference, and in accordance with the regulations.

No: Process C&D materials as non-asbestos containing.

STOCKPILERS OF C&D MATERIALS

Responsible persons include: Local government councils, commercial transfer stations, employers or self-employed persons who receive and stockpile C&D material.

Objective: Identify and remove any asbestos containing material prior to stockpiling.

Prior to Delivery of C&D Material

Stockpilers of construction waste and demolition material should:

- Advise all suppliers that asbestos and asbestos containing materials will not be accepted.

- Incorporate a ‘no asbestos clause’ in contracts and advise that loads will be rejected if asbestos is identified.

- Install highly visible signs indicating that no asbestos is accepted at the site.

- Ensure employees who will be supervising and conducting receipt and inspection of C&D materials are trained and, where appropriate, provided with suitable equipment to complete the task.

- Each site should have a ‘Site Health and Safely Plan’ that documents a safe system of work and assists in eliminating or minimising risks associated with the identified hazards.

Receipt of C&D Material

Is the building or structure from which the C&D material was sourced likely to contain asbestos?

Yes or uncertain: Receive material in accordance with the following guidance.

No: Process material as non-asbestos containing.

A thorough inspection of the C&D material is required prior to processing.

Gate Inspection Procedure

- Determine whether the guidance material applies (i.e. is the material likely to contain asbestos?)

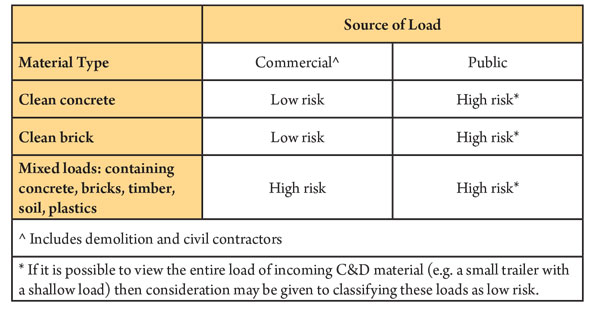

- Classify the material in accordance with the Material Risk Classification Matrix

- If material suspected of containing asbestos is sighted, the load should be rejected and the contaminated loads register completed. This register is to be made available for inspection to officers from WorkSafe and the EPA Victoria on request.

- Record receipt date, name and address of supplier, registration number of vehicle, estimated volume and risk classification of material for loads for which the guidance applies.

- Notify unloading supervisor of the risk classification. This could occur via phone or radio or information printed on the weighbridge docket, which is presented upon arrival at the unloading area.

- Provide instructions to the driver about the location of the unloading area and unloading process.

Unloading Vehicles

Reviewing the material during unloading assists to confirm the initial classification made upon arrival.

The site safety plan should be referred to when determining an appropriate system of work to enable material unloading and visual and/or physical inspection of loads.

A system of work should be in place to ensure that there is appropriate segregation of material being unloaded.

Unloading Procedure

- Ensure the person supervising the unloading of vehicles is aware of the material classification.

- Advise the driver to deposit the load in an area to ensure materials are not mixed with other loads.

- If the load is considered ‘low risk’, inspect the material by observing while the material is unloaded to confirm that no suspect asbestos-containing material can be identified.

- If the load is classified ‘high risk’ then the material needs to be unloaded and spread over a sufficiently large area to enable a comprehensive inspection of all sides of the material.

Records should be kept to ensure that the process from receipt of C&D material to the completion of the unloading procedure is auditable.

PROCESSORS

Responsible persons include: Operators of site based plants that crush and process the C&D material to produce a range of commercial recycled products and operators of mobile crushing plants.

Objective: To produce recycled product from C&D material that has been inspected in accordance with this guidance material.

To achieve this objective, processors need to determine if the C&D material been stockpiled in accordance with this guidance material?

Yes: Commence crushing in accordance with safe operating procedures (refer to the site health and safety plan). This crushing process should include monitoring the feed material and the removal of any extraneous substances.

No: Do not crush material. Consult with stockpiler. Ensure that an inspection process equivalent to that outlined above for stockpilers is undertaken prior to crushing material.

VENDORS

Responsible persons include: Sellers of recycled C&D material and operators who process the C&D material for their own use.

Objective: To test recycled product made from C&D material prior to sale.

Achieving this objective requires vendors of C&D material to test the product in accordance with the requirements of the regulations and confirm that the product meets the test requirements prior to re-use.

QUALITY CONTROL AND AUDITING

Responsible persons include: Stockpilers, processors and vendors.

Objective: To audit, review and improve the systems in place for recycling C&D material.

The person who has management and control of the recycled C&D material needs to ensure overall compliance with the relevant regulations.

Persons with control of each step in the recycling process should also regularly review their own compliance.

One means of assisting with achieving compliance is the conduct of regular (at least four per year) process reviews. Outcomes from the review should be utilised to improve processing systems and practices.

Records of the reviews and improvement strategies must be made available for inspection by officers from WorkSafe and EPA Victoria on request.

It is good practice for reviews to be conducted intermittently by a competent person who is not involved with the ‘day to day’ operation of the site.

For further information please refer to the “Recycling Construction and Demolition Material” guidance available from the WorkSafe website www.worksafe.vic.gov.au

You must be logged in to post a comment Login