MANAGEMENT COMMITTEE ISSUES (Issue 6)

SUBMISSIONS

EPA Draft Air Quality Improvement Plan

The draft SEPP for Air Quality has been released but does not include criteria for mines and quarries. The EPA is to develop an Industry Protocol on the PEM.

Environmental Guidelines

Work continues between the CMPA and DNRE to further develop environmental guidelines regarding Ground Vibration and Air Blast Limits for Blasting in Mines and Quarries, and Management of Water in Mines and Quarries.

MEMBERS ISSUES

Generic Document Release

At General Meeting #10, those present were offered the opportunity to purchase three generic books prepared by the CMPA for member’s use. These included:

- Employee Wage Book ($14.50 members; $16.70 non-members)

- Mobile Plant Operators Daily Safety Checklist Book ($13.00; $14.95)

- Safety, Environment, Maintenance and Material Concern Book ($4.50; $5.20)

- Visitors Register (electronic form, free for members)

All are available through the Secretary

Other documents under development include a suggested Chart of Accounts for which feedback has been sought and the General Information Reference Manual.

Marketing Quarries

A member contacted the Chairperson during December 2001 with details about a contract for which that company was unable to submit a proposal. The purchaser’s details were provided and the job opportunity transferred to another CMPA member better positioned to undertake the work.

CMPA a member of VECCI (Victorian Employers Chamber of Commerce and Industry)

For all your needs contact your Regional Co-ordinator who will then discuss your concern with our VECCI Representative Warren West. Members present at General Meeting 10 appreciated the opportunity to meet and talk with Warren.

Should you wish to have direct access to VECCI and it’s member services, then ensure you obtain the 25% special discount available to CMPA Members.

Thank you to those who responded to the impact of Public Liability Insurance Premiums Survey.

Appointments within the Management Committee

Raymond Walsh was appointed as Deputy Chairperson, and Bruce McClure was appointed as Public Officer.

Alan Wilkins will represent the CMPA on the Quarry Managers Advisory Panel for the next twelve [12] months, whilst Kevin Donohue and Rod North agreed to be introduced into the process over this period with the intention of undertaking representation for a set period.

Congratulations and thank you all for your commitment.

Bill Gread has tended his resignation from the Management Committee. We thank Bill for his contribution and on behalf of all members offer best wishes for his future health and happiness.

The Committee now calls for expression of interest from owners who produce less than 200,000 tonne per annum to fill this vacancy on the Committee.

Post Compaction Testing – Inclusion in members Conditions of Sale ‘Material Warranty’

The Management Committee recommends addition of the following clauses into member companies Conditions of Sale.

- (Company) warrants that all materials supplied comply with stated specifications at the time of supply.

- The customer warrants that following the supply of materials that (Company) is not liable to the customer as a result of any action which may be taken by the customer, its servants or agents, which results in altering the specification of the materials.

VMEC – Risk Assessment Workshop

Sarah Kerr attended the ‘2001 Safety Workshop’ organised by the Victorian Minerals and Energy Council late last year that discussed the subject of ‘Risk Assessment’. Professor Jim Joy, Director of the Queensland University Minerals and Safety Centre, presented the course.

The risk of death working in the Australian mining (including underground, surface and quarries) industry is one in 3500. In Australia an industry is considered to be safe when that risk is one in 100,000.

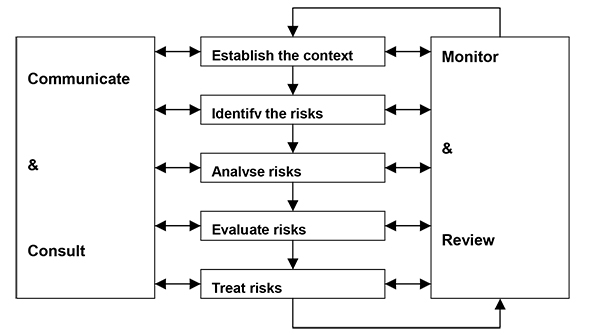

A pro-active approach to risk management is needed for industry to achieve this level. Planing to achieve this level will improve the overall quality of a business. Australian Standards (AS/NZ 4360) has produced a process model for risk analysis as follows:

In order to understand the diagram, the definition of Hazard and Risk is as follows:

Hazard refers to a ‘source of potential harm or a situation with the potential to cause a loss’.

Risk on the other hand is the measure of a hazard, a measure of the chance of something going wrong. In mining, this leads to the conclusion that the industry is inherently very hazardous but these hazards must be controlled and managed to ensure minimal risk.

Analyse risks

There are three [3] options available for calculating the risk. Which one is used is dependent upon what the RA is for, however in general semi qualitative is the most applicable.

- Quantitative: gives the actual figure to the risk. It requires a lot of thought and is only for the very experienced.

- Qualitative: Risks are classed as one of high, medium or low. (Not all that useful.)

- Semi-qualitative: This is the most common and easiest to use. It requires the use of a semi-qualitative table that ranks the risk, however, it is important to note that a consequence cannot change when a control is implemented.

Evaluate risks

Once the risks are ranked, one must go through them in the order of first to last putting in controls to reduce the probability that the event occurs. It is very important that when this is being carried out the hierarchy of controls is used (Eliminate, Substitute, Engineer, Administration, PPE).

Tools for Risk Assessment

To carry out a RA, it is important that a team of the best people is used and that adequate time is allowed. This means that RA costs are high but if such a team is not used, there is little chance of the proposed changes being taken up by the workforce. Tools available include:

- Job Safety Analysis [JSA]

- Workplace Risk Assessment and Control [WRAC].

- Failure Modes, Effects & Criticality Analysis [FMECA].

- Hazard and Operability Study [HAZOP].

- Fault Tree Analysis.

Sarah considered attendance at this workshop worthwhile and the information will be useful for our upcoming Reference Manual for Risk Assessment.

CMPA Rules

An application has been lodged and approved by Consumer and Business Affairs Victoria.

Associates (Suppliers) Committee

The first meeting of the Associates Committee was held at Komatsu’s premises in Campbellfield on 4th February 2002. Andrew Lambing of Komatsu was appointed as Chairperson, and in this capacity Andrew will represent all Associates on the Management Committee.

Mike McCann of Jaques was appointed Deputy Chairperson and Mark Whitla of Melbourne Finance Broking was appointed Secretary. Inaugural Committee Members include Sharon O’Donohue of Landmark Contracting, and Frank Santoro of Orica Australia.

Following election of office bearers John Mitas and Ian McLeod of the DNR&E raised the issue of manufacturers responsibility to comply with the requirements of Section 24 of the Occupational Health and Safety Act, and went on to present information on two recent incidents where employees suffered injuries after falling from mobile equipment.

The next Associates Meeting is planned for Thursday 23rd April 2002 at Jaques, 447 Auburn Road Hawthorn East, from 7.00am.

Small Business Innovation Fund – Conveyor guarding and tracking Isolation in Plants which fall within guidelines

The Management Committee is considering an application for funds to improve conveyor guarding and tracking isolation to reduce specific site incidents. The Small Business Innovation Fund has been set up to assist businesses employing twenty [20] or less employees to reduce specific site incidents through financial partnership.

SAFTEY AND ENVIRONMENTAL INFORMATION

Fatal Accidents recorded in our sector

The DNRE advised us that on 7th November 2001 a hire company representative died when a cherry picker rolled at a surface nickel operation

A second fatality occurred on the 19th November 2001 at OK Tedi Mines Dredging Project in PNG, when a Surveyor was buried under the toe of a collapsed Bund Wall.

Penalty paid following death of plant operator

The DNRE advised of a small family business being fined $112,000.00 following an accident in which a plant operator died when a grader rolled over him. The equipment was not in acceptable condition and the owner had failed to carry out repairs in a timely manner.

EDUCATION

Practical Training for Potential Quarry Managers

The principal issues for the CMPA to address on education for managers, includes subject content, the periods through the year training should occur, hours in the college and on the job, pre-entry requirements, course content, examination and support for students, and a more practical set of certificates with a state based focus. A means to address these issues is outlined under item 2 below.

National Mining ITAB

Our chairperson represented the CMPA at a first meeting of the Project Steering Committee held in the DNRE Offices on 13th December 2001.

Ron Kerr asked to be provided with a listing of all new and old competencies under consideration, plus a short written explanation to cover each competency objective. The CMPA also requested that Box Hill Institute be offered a position on the Committee, in recognition of their thirty [30] year relationship with our industry.

Other issues of concern to included the difficulty where competencies overlapping and the lack of recognition outside of the industry for completed competencies.

The Management Committee last month nominated Ron Kerr to be the CMPA Representative on the Project Steering Committee formed to review the Extractive Industries Training Package. You can assist Ron in achieving the best outcomes from this process by contributing as outlined in the copy of Des Caulfield’s speech repeated in this issue under Section 6 as the Feature Article.

Work Safely Training

Approval has been granted by DEST for WELL funding in the order of $118, 406 (DEST: $88,694; Members: $29,712) with the contract being signed on January 17.

This has been secured to roll out the CMPA Work Safely Reference Manual! This exciting new opportunity will assist all persons working in quarries in meeting their obligations under the Extractive Industries Development Act, through achieving

- Extractive Industries Certificate II – Work Safely competency

- CMPA Industry Induction Card.

Benefits of training include:

- Meeting obligations under the OH&S management system guidelines;

- Creating a greater awareness of employer, employee, contractor, and supplier responsibilities;

- Creating a productive learning environment on site;

- Assistance in employee career development; and

- An increased understanding of safety implications and potentially an ability to minimise exposure when submitting insurance claims.

Experienced in the extractive industries, the training team from Box Hill Institute are able to ensure an understanding of the safety competency across all levels of participant educational/ language backgrounds. Between the program sessions, participants will be visited on site to assist them towards successful completion of the program.

Currently two pilot programs are open for applications with a further 14 programs set to be run around the state in the second half of 2002.

The initial program’s Session 1 was held from 9.00am to 4.00pm at DNRE Bendigo on Friday 22nd March 2002, with Session 2 planned for Friday 26th April 2002 at the same location and times.

The second program Session 1 will be presented on Thursday 18th April 2002 at Northern Quarries Epping from 9.00 to 4.00pm, with Session 2 planned for Friday 3rd May at the same location and time.

Please contact the Secretary for further information.

Summer School organised by the Australasian Institute of Mining and Metallurgy

The CMPA was invited by the above body’s Education Endowment Fund to arrange an informative morning tour of one or more sites on 17th January 2002, designed for forty [40] post Year 11 ‘High Achievers’, and their chaperones. The DNRE offered to assist the CMPA in this important task.

The group commenced the day with a tour of Northern Quarries Plant at Epping, with a presentation covering geology of the site by Basil Natoli, followed by a presentation from Peter Kavanagh covering operation of the plant.

The group then travelled to Recycling Industries at Laverton where David Bell outlined the safety regulations the group needed to follow and then led a the tour around the facility.

During lunch at the AB Shaw Reserve, Sara Harbridge of the DNRE discussed the role of her department.

The students found the morning very informative and asked for information on employment opportunities in our industry. It would be in our best interest to develop a job pathway for students, and to ensure that it is published in study guides available to them.

You must be logged in to post a comment Login